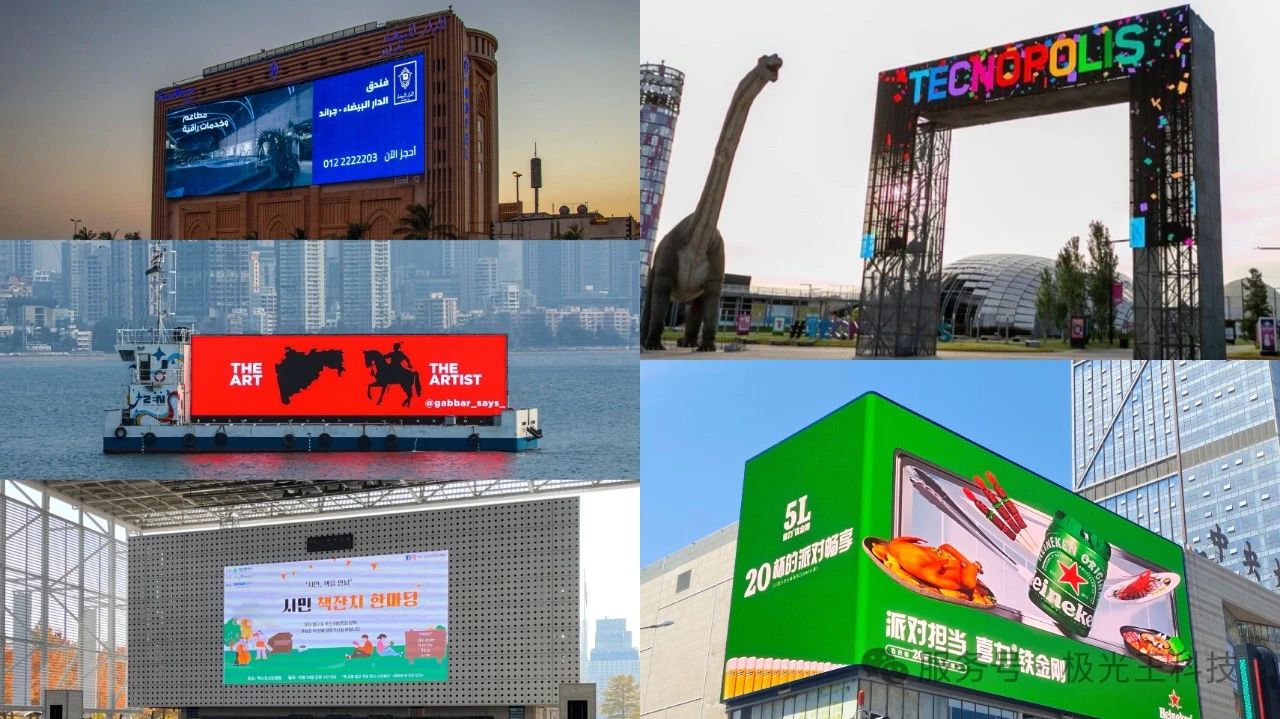

In today's digital era, LED displays have become iconic symbols of urban modernization. From colossal advertising screens in bustling commercial centers to live event displays in stadiums, from smart information boards at transit hubs to artistic installations at city landmarks—these vibrant visual carriers are all backed by Kingaurora's relentless pursuit of perfection. As an industry leader, Kingaurora adheres to the core philosophy of "Quality Creates Value," crafting outdoor LED displays that stand the test of time. Join us on an exclusive tour of Kingaurora's production base to witness the meticulous journey from raw chips to finished products.

In Kingaurora's workshop, the "heart" of the display—the DIP570 Tri-Color LED—is manufactured with precision. Each imported LED chip undergoes three rigorous screenings to ensure:

Wavelength consistency within ±2nm

Uniform brightness and voltage parameters

25μm gold wire bonding for electrode connections

DIP570 Tri-Color LED Features:

✔ RGB Integration: Combines red, green, and blue chips for high luminous efficiency at lower current

✔ Advanced Thermal Management: High-conductivity silver adhesive (>25W/m·K)

✔ UV-Resistant Epoxy: >95% light transmittance for optimal optical performance

The module, as the core unit of the display, exemplifies precision manufacturing:

PCB Preparation: Precision baking to remove moisture, followed by solder paste application (0.1–0.15mm thickness).

SMT Process: High-speed placement machines (±0.01mm accuracy, 5,000 solder points/hour).

Wave Soldering: Ensures reliable connections for inserted LEDs.

Protective Coating: Conformal coating for circuit protection.

Testing: Zero dead pixels, no shorts.

Structural Assembly:

Base shell installation

Automated screw fastening

4-hour preliminary aging test

Potting with high-thermal-conductivity sealant (>1.5W/m·K, IP68-rated)

8-hour secondary aging

Protective mask installation

Final inspection: >95% brightness uniformity, color consistency

Assembly Process:

Waterproof gaskets for sealing

Patented quick-lock mechanism (<30s installation)

Seam precision <0.1mm

Thread-locking adhesive on screws

20-minute water spray test (IP68 validation)

48-hour continuous aging

Environmental Reliability:

48-hour exposure to 70°C

Cold start at -40°C

Mechanical Durability:

100,000 button presses

5,000 cable bends

Vibration resistance

Optical Performance:

Spectral analysis

Brightness decay monitoring

Color uniformity verification

From chip selection to final product, Kingaurora’s manufacturing process embodies China’s shift from "Made in China" to "Created in China." As a 16-year leader in outdoor LED displays, Kingaurora’s products are globally recognized for:

High Brightness & Energy Efficiency

Superior Thermal Management

Extended Lifespan

Every meticulous process and stringent parameter reflects Kingaurora’s dedication to quality. This 16-year craftsmanship has made its displays shine worldwide, representing the pinnacle of "Intelligent Chinese Manufacturing." Moving forward, Kingaurora will continue to innovate, delivering even more exceptional visual experiences.

3th Building,Gaosite Zone Pingshan

New District, Shenzhen

sevice88@kingaurora.com

3th Building,Gaosite Zone Pingshan

New District, Shenzhen