In today's rapidly developing LED display technology, traditional DIP LED beads still occupy an irreplaceable important position. Since the advent of LED display technology, it has undergone multiple technological changes and innovations. In this evolutionary journey of display technology, DIP (Dual In-line Package) LED beads, as the earliest packaging form, have not only witnessed the development of the LED industry but also maintained continuous market competitiveness in specific application scenarios.

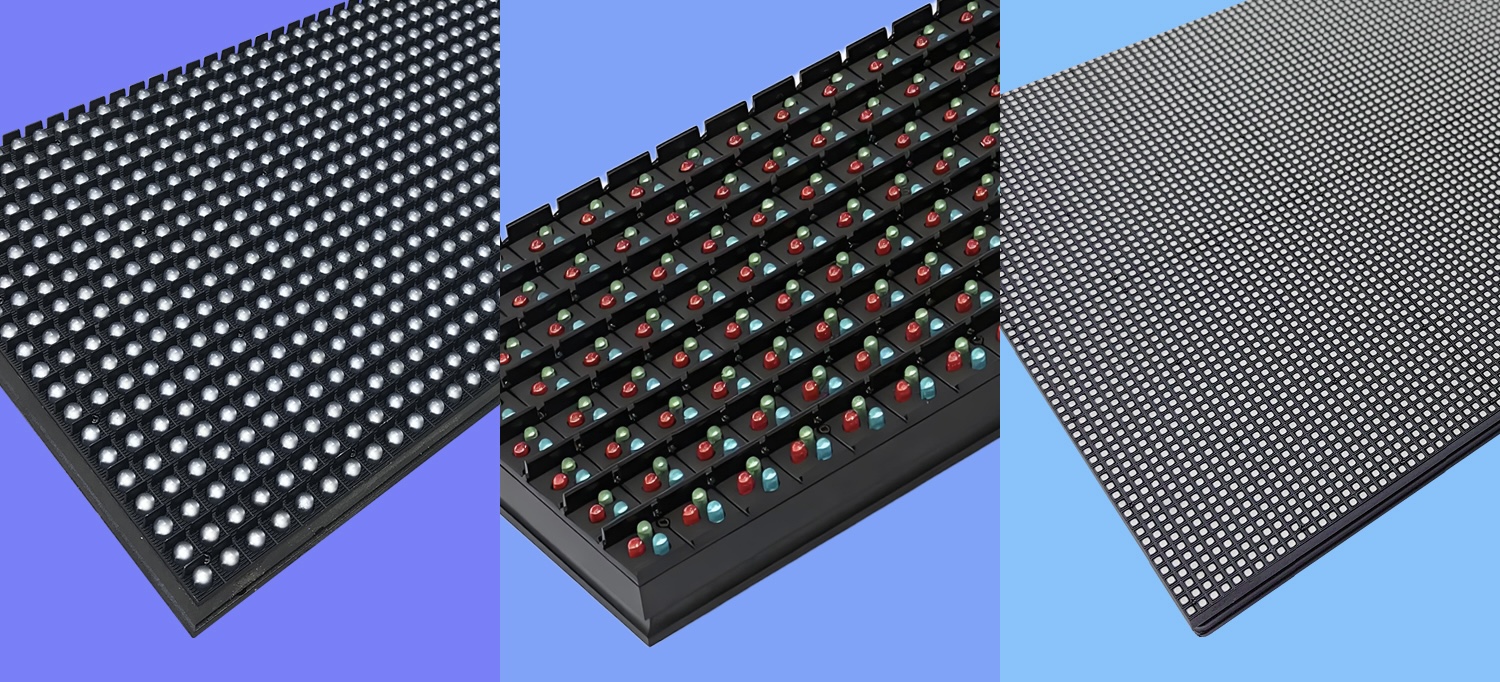

DIP packaging, an abbreviation for dual inline-pin package, commonly known as plug-in display screen, is the first developed technology in LED packaging modes. As early as the initial commercialization of LED technology, DIP packaging became the main technical path for LED displays with its simple structure and reliable performance.

DIP LED beads have evolved from initial single-color indicator lights to the most stable and durable light source technology for outdoor displays, undergoing multiple upgrades from monochrome to full color, from basic brightness to high brightness and energy saving. Traditional DIP has continuously optimized stability, heat dissipation, and waterproof performance, while in recent years, high-brightness energy-saving packaging represented by Kingaurora DIP570 has achieved industry leap: brightness can reach 10,000-12,000 nits, power consumption decreases by 30-40%, with longer lifespan and higher color temperature consistency, especially suitable for strong sunlight and extreme environments. Future DIP technology will continue to develop towards higher light efficiency, lower energy consumption, higher reliability, and smaller pixel pitch, consolidating its core position in outdoor high-brightness displays.

DIP346, as a representative of traditional plug-in packaging, adopts φ3.0mm circular structure design and is one of the earliest commercialized LED packaging forms.

· Brightness output: 5000-7000nits

· Protection level: IP65

· Operating temperature: -30℃ to 80℃

· Service life: 5-7 years

· Two-pin plug-in design

· Standard 2.54mm pin spacing

· Independent epoxy resin packaging

· Basic bowl-shaped optical structure

Kingaurora DIP570 represents the latest development achievement in plug-in packaging technology, achieving qualitative performance improvement through multiple technological innovations.

· Three-in-one integrated packaging technology

· Patented optical lens design

· Innovative bowl-shaped structure

· Light gathering efficiency over 85%

· Ultra-high brightness: 8000-10000nits

· Energy efficiency improvement: 30% energy saving

· Enhanced protection: IP68 protection level

· Extended lifespan: 8-10 years service life

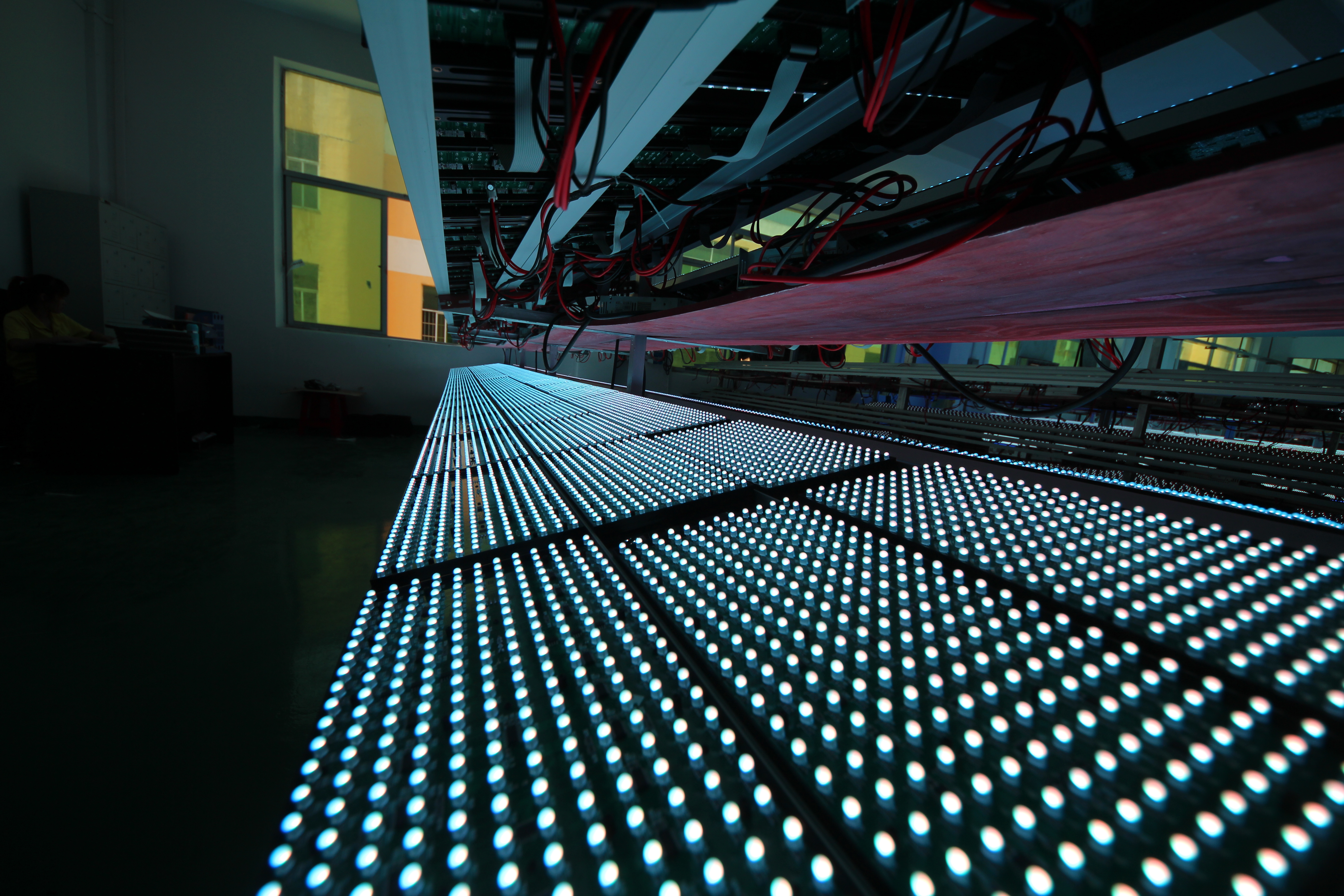

DIP LED beads have significant advantages in outdoor display applications. Due to their robust packaging structure and typically using epoxy resin packaging, DIP LED beads perform excellently in protection performance, effectively resisting moisture, dust, and corrosion in outdoor environments.

The brightness output of DIP LED beads is significantly higher than many other types of LED beads. The high brightness characteristic enables DIP LED beads to maintain clear visual effects even in direct sunlight outdoor environments, making them ideal for applications such as outdoor billboards, stadiums, and traffic indicators.

Despite the emergence of new packaging technologies, DIP technology still maintains a strong market position in the outdoor large-pitch display field. Currently, DIP can still occupy a strong market share in outdoor P20-P8 markets, especially in outdoor displays with pixel pitch P6 and above, DIP remains the mainstream choice.

Another market advantage of DIP LED beads lies in their cost-effectiveness. Due to the mature production process of plug-in LED beads and numerous manufacturers, their prices are relatively low, giving them significant competitive advantages in cost-sensitive situations.

A major limitation of DIP LED beads lies in their viewing angle range. Due to their packaging method and design characteristics, the viewing angle of DIP LED beads is not easy to fix accurately, generally between 100-110 degrees. Compared with other packaging forms of LEDs, there is a certain disadvantage in viewing angle range.

The production organization of DIP displays is relatively complex, making it difficult to implement mechanized production, resulting in low production efficiency. Since manual circuit board insertion is required, DIP LED beads are difficult to achieve fully automated production, which makes them lag behind new packaging technologies such as SMD in production efficiency.

Despite facing competitive pressure from emerging technologies, DIP LED beads still maintain considerable vitality in specific market areas. With the continuous progress of technology and innovation and upgrading of LED technology, the performance of DIP LED beads will be further improved.

· Adoption of more advanced light-emitting components and drive circuits

· Higher brightness, better color reproduction, more stable light output

· Intelligent integration and environmental adaptability improvement

· Material science innovation and energy efficiency optimization

With increasing global attention to energy crisis and environmental pollution issues, energy saving and environmental protection have become important development trends in the LED lighting market. As energy-efficient lighting products, DIP LED beads are expected to continue leveraging their weather resistance and stability advantages in outdoor and semi-outdoor environments under government policy promotion.

3th Building,Gaosite Zone Pingshan

New District, Shenzhen

sevice88@kingaurora.com

3th Building,Gaosite Zone Pingshan

New District, Shenzhen