In the outdoor LED display industry, mesh screens have become the preferred choice for building facades, high-altitude advertising, and sports venues due to their high transparency, lightweight design, and wind resistance. However, with DIP (Dual In-line Package) and SMD (Surface Mounted Device) as the two dominant technologies, many clients face confusion when selecting the right product.

This guide provides a detailed comparison across four dimensions—technical principles, performance, applications, and cost efficiency—to help you make the best decision for your project.

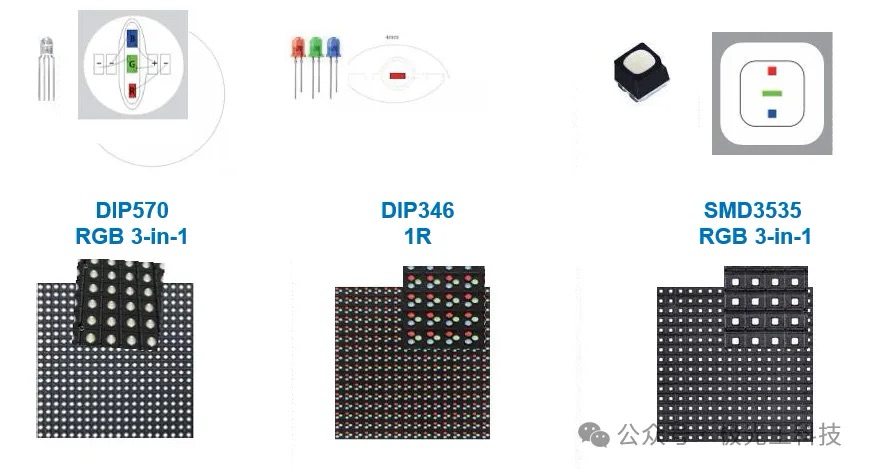

Physical Structure: LED beads are inserted into PCB holes and soldered in place.

Light Emitting Unit: Traditionally uses discrete RGB beads ("3-in-1"). Kingaurora’s DIP570 integrates three LED chips into one package.

Optics: Independent lens structure for strong directional light.

Protection: Fully resin-sealed for superior weather resistance (IP65-IP67).

Physical Structure: LED chips are mounted directly onto the PCB surface.

Light Emitting Unit: RGB chips integrated into a single package.

Optics: Planar light emission for wider viewing angles (140°-160°).

Protection: Relies on encapsulation gel and coatings (typically IP54-IP65).

| Feature | DIP Mesh Screens | SMD Mesh Screens | Technical Insight |

|---|---|---|---|

| Brightness | 8,000–10,000 nits | 5,000–7,000 nits | DIP’s lens focuses light better |

| Viewing Angle | 100°–110° | 140°–160° | SMD emits light more evenly |

| IP Rating | IP65–IP67 | IP54–IP65 | DIP’s sealed structure wins |

| Heat Dissipation | Metal pin cooling (ΔT ≤15°C) | PCB cooling (ΔT ≤25°C) | DIP has lower thermal resistance |

| Shock Resistance | Excellent (secure soldering) | Good (requires reinforcement) | DIP’s pins are more durable |

Long-distance visibility (e.g., highway billboards, airports, skyscrapers)

Harsh climates (deserts like Dubai, coastal cities like Sanya)

24/7 reliability (power plants, traffic systems)

Close-up displays (shopping malls, luxury storefronts)

Creative shapes (curved screens, custom designs)

Temporary events (concerts, exhibitions)

| Factor | DIP Mesh Screens | SMD Mesh Screens |

|---|---|---|

| Upfront Cost | 15–20% lower per unit | Higher unit cost |

| Installation | Requires robust framing | Faster/easier setup |

| Maintenance | Lower per-LED repair cost | Module replacement costly |

| Energy Use | High brightness = higher draw (but DIP570 saves 30%) | Better efficiency in mild temps |

Choose DIP if:

Viewing distance >20m

Extreme weather (heat, sand, rain)

Budget favors initial savings

Choose SMD if:

Viewing distance <10m

Indoor/outdoor transitional zones

Content is video-heavy

Why Kingaurora’s DIP Mesh Screens?

✔ Extreme durability: Patented DIP570 beads (IP67, -40°C to 70°C range)

✔ High brightness + efficiency: 8,000–10,000 nits, 30% energy savings

✔ Low maintenance: Ultra-thin, lightweight, front/rear serviceable

Kingaurora: 16 Years of Outdoor Expertise

Our engineering team provides custom solutions for DIP or SMD mesh screens, ensuring the best ROI for your project.

3th Building,Gaosite Zone Pingshan

New District, Shenzhen

sevice88@kingaurora.com

3th Building,Gaosite Zone Pingshan

New District, Shenzhen